Large Size Bearing Repair

Meet the world of bearing reconditioning for budget savings and lower carbon emissions!

It is possible to have your valuable large size bearings repaired by manufacturer's quality assurance and re-use them up to 2 times.

Advantages and benefits of professional bearing remanufacturing services are:

-

Reduced total life cycle costs

-

Longer bearing service life

-

Shorter bearing delivery lead time

-

Shorter machine breakdown time

-

Less negative effect on environment

-

Protection of spare bearing stock

How are the bearings reproduced?

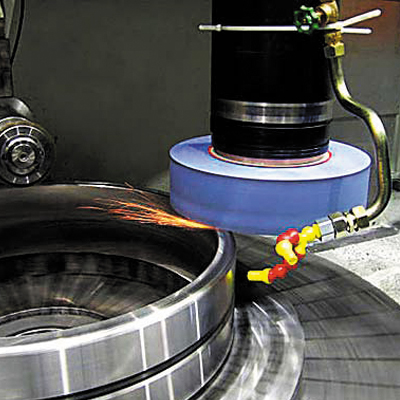

Remanufacturing process starts when our bearing analysis experts come on-site to inspect the condition of your large size bearings. After their initial inspection, they prepare a detailed report explaining the required remanufacting methods in order to bring the bearings back to the condition required for your application. If your bearings are found suitable for remanufacturing, they go through a process using basically the same manufacturing standards, processes,equipment and quality assurances as new bearings. In SKF’s remanufacturing process, all functional surfaces are reconditioned and if necessary bearing components are replaced. As a result, combined with a proper predictive maintenance program, potential service life of your bearings will be increased substantially.

For further information; teknik@unluteknik.com