- Bearings

- Mechanical Power Transmission

- Electric Motors

- Gearboxes

- Linear Motion

- Seals

- CirClips

- Lubrication and Filtration Solutions

- Service and Maintenance Products

- Bearing Mounting Tools

- Bearing Dismounting Tools

- Alignment Tools

- Condition Monitoring Tools

- Portable Vibration Measuring Devices

- Operator Based Maintenance & Field Observation

- Online Machine Protection Systems

- Wireless Online Monitoring Systems

- Online Monitoring Software

- Sensors

- Industry 4.0

- Electric Motor Analyzers

- Bearing Heaters

- TKTI Series Thermal Cameras

- TKSA Series Shaft Alignment Tools

- Automotive Spare Parts

- Hand Tools

- Power Tools and Accessories

- Abrasives

- Plasma Cutting Systems

- Adhesives& Repair-Maintenance Spreys

- Protective Gloves

- Oxo-biodegradable Plastic Additive

Online Status Monitoring Systems

Vibration analysis is a unique solution the part of predictive maintenance that save "Machine Health" which affects production efficiency. Vibration analysis has been carried out offline for many years with portable devices. However, in today's world where criticality has increased and unexpected downtime causes greater damage to the business. Online monitoring systems provide instant monitoring of machines.

The field data, traditionally collected by portable devices, can be collected continuously and more efficiently with built-in and compact devices. In this way, while preventing losses between measurement periods, changes in critical systems that are constantly monitored can be followed. Thanks to online condition monitoring systems, it is possible to intervene in production when necessary or to make planned stops without causing secondary damages.

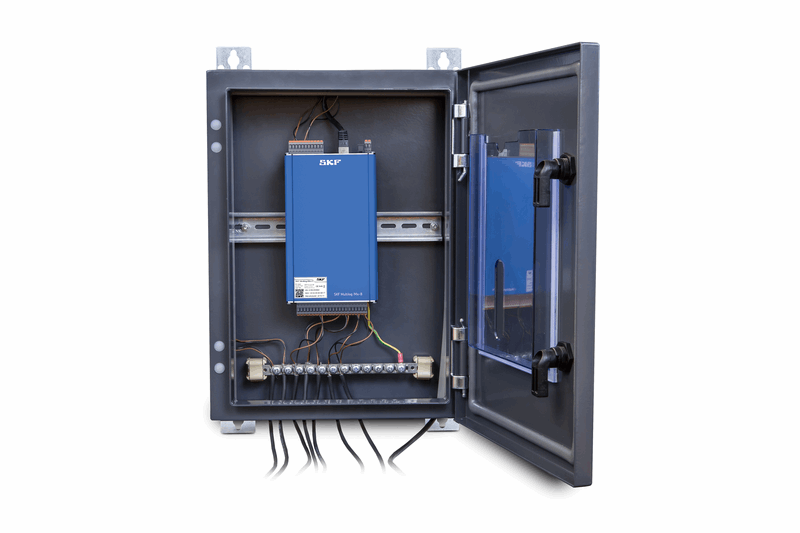

- SKF MULTILOG:

The SKF Multilog Online System is an efficient solution for 8 and/or 16 channel condition monitoring applications requiring fewer channels. It offers a complete system that helps detect and prevent malfunctions before they happen, provides pre-advised recommendations for machine condition, and provides advanced condition-based maintenance that improves reliability, active uptime and performance.

- ABB SMART SENSOR

ABB smart sensors monitor your electric motors, bearing housings and pumps and increase their performance, efficiency, reliability and service life. Pocket-sized wireless sensors can be connected to almost any low voltage motor, all bearings and some pumps, and from there to the ABB Ability-Industrial IoT platform. Operating data is transferred to a secure cloud-based server. The collected data is analyzed and converted into feedback and sent directly to your smart devices.

Smart sensors support the rotating equipment performance in plant and ensure maximum efficiency and value.

Product Groups

|

|||

|